Fusion Edge

|

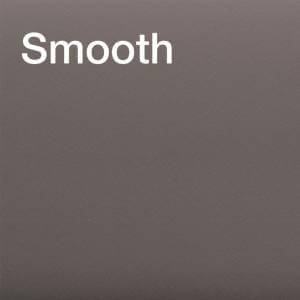

Seamless bonding with Döllken FUSION-EDGE, for all joining and thermal technologies With its FUSION-EDGE, Döllken has designed a revolutionary coating, creating a seamless unity of edgeband and board. FUSION-EDGE is a high-tech product and it is a true alternative to glued edging, since this innovative furniture edging requires no additional hot melt adhesive. Your benefits by using Döllken FUSION-EDGE:

The new joining methods offer visually zero joints, eliminating the possibility of accumulation of dust and moisture between the edgeband and the board. These methods also offer increased production reliability and increased productivity.

The Döllken FUSION-EDGE functional coating will impress with its excellent initial adhesion and its minimal energy requirements compared to other products. Performance fluctuations, which the contractor would need to re-adjust, are unknown when working with Döllken’s quality products.

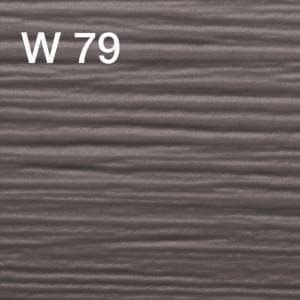

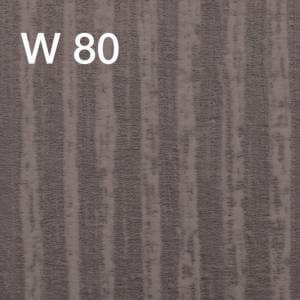

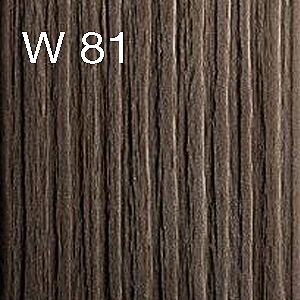

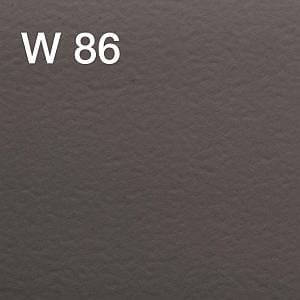

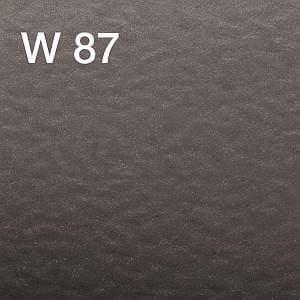

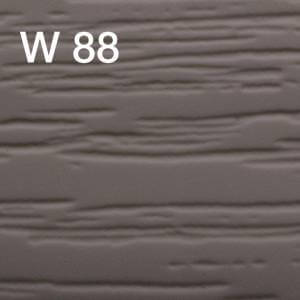

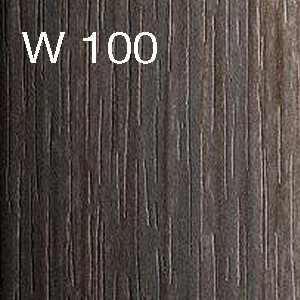

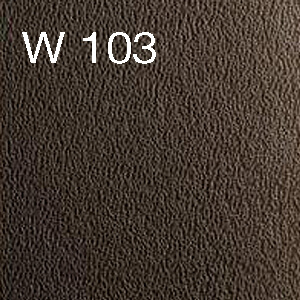

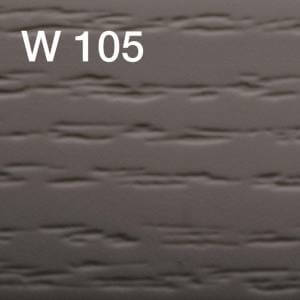

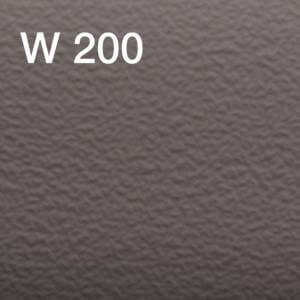

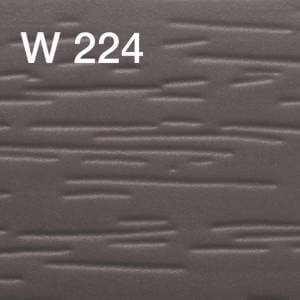

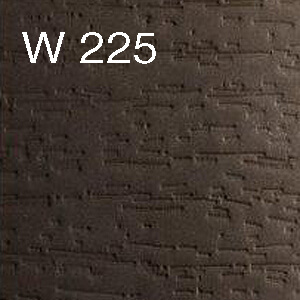

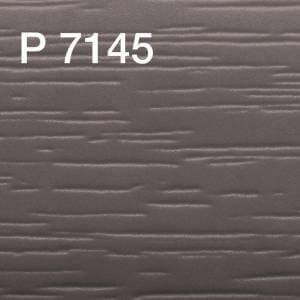

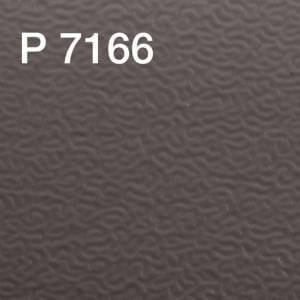

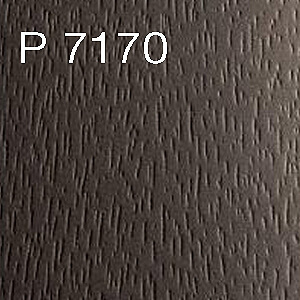

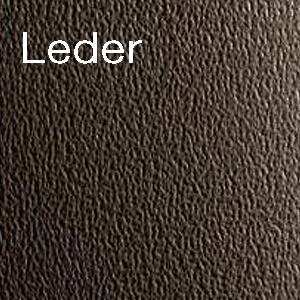

All Instant Edging Programme (KSP) ABS and 3D colours and finishes and all thicknesses and widths, now are available also on order as FUSION-EDGE, starting from one roll.

|

|||

|

|

|

|

|

Döllken FUSION-EDGE may be applied using any currently available innovative joining technology and heat source. This includes not only the well-known laser method but also plasma and hot air technologies as well as the NIR process. Döllken FUSION-EDGE can also be produced in individual colours and finishes from ABS and also from PP and 3D (acryl) on your request in all thicknesses and widths. If you are interested in Döllken FUSION-EDGE and would like receive more information, please do not hesitate to contact us: E-mail: btulinde@btulinde.com Tel. +371 29227796 Office: Krustabaznicas street 4, Riga, Latvia (map) |

|||